THREE years after the launch of “accord 500” and “accord 600” by SCM Group, solutions which have dramatically changed the rules of play in the production of doors, windows, staircases and solid-wood elements, new finishing upgrades to the range, for machining the panel and the furniture world, but always “According to wood”, starting from the intrinsic peculiarities of the material machined and the client’s most pressing demands, have been announced.

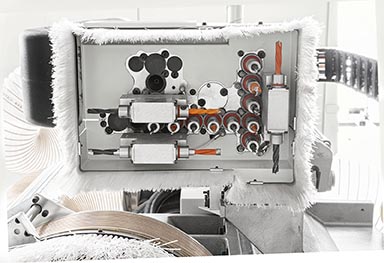

The strong points of this range, which has conquered leading clients at international level, remain unvaried, such as the dual motorised “gantry” structure, the 5-axis operator unit with excellent performance, the innovative suction systems to guarantee maximum cleaning of the machine and the surrounding environment, the high-capacity tool magazines with Maestro power TMS intelligent management system and the CAD/CAM Maestro Lab software for designing and programming.

The latest upgrades from SCM Group are:

The “Optizone” patented system connected to the Maestro Lab software, which is revolutionising the CNC bar machining centres: with a simple click, the size of the two work areas can be defined as early as the programming stage, based on the pieces to be machined. This function is also available for the clamps.

New SVP (Single Vacuum Pods )function to independently secure the pieces on each semi-table: it is possible to have several separate vacuum areas, and the pieces can be loaded onto the machine by activating one suction unit at a time. This allows for excellent management of the scraps.

The two functions mentioned above, developed to deal with the vacuum, are particularly useful in the case of asymmetrical machining areas.

An increase in the length of the 1900 mm y-axis work surface compared to the current 1600 mm y-axis enables the operator to carry out horizontal machining more effectively and simply inside the pieces blocked with clamps with the 5-axis electrospindle.

Greater configurability of the operator unit with new boring and drilling heads and new multifunction units is also available.

The new chain tool magazine, Quadro 35, positioned on the rear side of the mobile gantry-type structure, is considered ideal for those always needing numerous tool positions easily and rapidly to hand in a reduced space.

As Bruno Di Napoli, Business Unit Manager for SCM’s machining and drilling centres explains: “Once again leading all the developments in these new solutions is the will of the company to place the client and their experience in using the machine at the centre of everything.

“Whether we are dealing with aspects of software programming, digital connectivity or ergonomics and ease of use, we aim to ensure the operator always works under maximum safety conditions without compromising in any way on practicality and production efficiency”.

See page 36-37 of our February/March 2025 issue on our Back Issues page.