TUSCANY, in the heart of Italy, has always provided the world with sophisticated technology. Here, SCM boasts a highly specialised industrial facility which, in recent years, has grown gradually and significantly to provide the timber construction industry with ever more innovative, smart and connected solutions.

SCM’s new entries were presented from 13 to 15 March at the “Timber Construction Days” open house. These include the greatly anticipated new CNC Machining centre OIKOS XS 650, the latest in the OIKOS range with all its advantages while offering improved performance, greater productivity and flexibility when machining beams with a cross-section up to 650 x 310 mm.

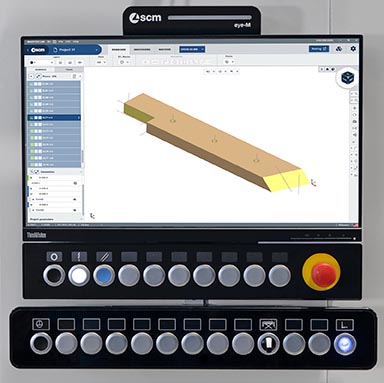

The event also shone the spotlight on Maestro lab beam&wall, the SCM software dedicated to all AREA and OIKOS CNC machining centres and developed on the new CAD/CAM Maestro lab, to the advantage of the machine’s features and the operator’s experience of use.

A great deal of attention was placed on the digital services enabled by data, especially the new version of the IoT platform, Maestro connect, a monitoring application for the performance and productivity of connected machines.

The official inauguration was held at the modernised industrial plant during the open house. The existing plant is now not only 50% larger but will have a further 3,000 m2 of production space, totalling 10,000 square metres overall. An expansion aimed at increasing production capacity and optimising internal logistics, in order to promote competitiveness and technological innovation.

Innovation, digital transformation and much more: at the “Timber Construction Days” there were also prominent industry experts from customer companies, partners and institutions, all of them working with SCM. A vast programme of presentations focused on key topics in the sector like the digital transformation in mass timber, the future of timber construction in Industry 4.0 and on case studies concerning successful projects in different countries.

“In line with the high demand from the timber construction industry, both in Europe and overseas, we have speeded up our R&D path and we are proud to showcase the many results at the open house next March” says Tommaso Martini, business unit manager for CNC Machining Centres and Systems for Timber Construction, speaking before the event. “We started out with the production needs linked to the construction of timber buildings using mass timber and moved towards promoting a new concept of ‘smart timber’. We did so with solutions that allow our customers to make their processes smarter, optimising workflows, saving on material and covering a wider spectrum of applications”.

At “Timber Construction Days”, it was possible to directly assist in the presentation of what’s new as well as take a guided tour of the factories and see other models, such as OIKOS XS 450, OIKOS X, OIKOS XL and AREA X, designed for machining different kinds of beams and CLT elements. SCM’s additional technologies for machining CLT panels were also presented: sanding machines and double-end profiling machines.

As with all the most important events in the industry, the Swedish company Randek wwas present, an SCM partner supplying complete systems for the timber frame sector.

Lastly, there were numerous technological partners who have been working with SCM for some time supplying complete customer solutions: tool suppliers and software houses such as Oertli, Leitz, Cadwork, Hsbcad, Sema, Dietrichs and Innorenew.

SCM opened its doors to customers and partners to present its latest technological innovations, discuss the industry’s new trends and show off its production plant. A unique opportunity to discuss with experts, expand their knowledge and discover the competitive solutions and advantages that SCM can offer.

See page 13 of our April/May 2025 issue on our Back Issues page.